Sandblasting was most commonly used for cleaning and removing varnish from wood. It has become indispensable, being a much cleaner, prettier and more effective alternative to ordinary treatments with brushes in the wood processing industry! However, in recent years it has been used more frequently for decorating as well as designing and refining surfaces, giving the material completely new value, but also offering more versatile possibilities for design!

Blasting wood

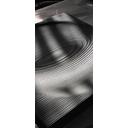

Depending on the duration, the blasting material and the wood type, the most diverse results are achieved with sand- or glass bead blasting. The result is always an even and natural looking surface. The stronger and longer the blasting process, the easier it is to create a slightly or even strongly weathered impression, which provides softwood with a particularly smooth and beautiful look. Regarding hardwood, the surface remains rather even. Wood pores are worked out particularly clearly, which is very useful when it comes to modern surfaces. The range of our offerings is significantly increased by providing effects that can be achieved by blasting parts of, or patterns on the items. This provides wood industry professionals with endless design opportunities for use in the manufacture of high-quality furniture.

Application and technique

Examples of materials that can be sandblasted

Solid wood components of all types of wood, untreated or with surface finishing. Veneered parts of all types of wood, untreated or with surface finishing. Wood materials of different qualities.

Examples of application

- Furniture manufacture

- Renovations

- Removing varnish from wooden surfaces

- Cleaning of old wooden surfaces

- Furniture surface rustic-style

- Modern surface effects

- Decorative design with patterns, logos and letterings on even surfaces

- New furniture components in rustic style

- Kitchen fronts, window frames, furniture, wooden doors, sculptures, etc.

Blasting material

- Corundum

Technical information and processing details

Depending on the density and the hardness of the wood, a kind of antique effect is created, which resembles authentic weathering. Unlike texturing brushes like rustilon or brass, which remove the soft parts of the wood and where the scratches of every single brush strand can be seen on the surface, sandblasting creates an absolutely smooth and natural weathering effect, which can never be achieved by merely using a brush! Blasting removes the soft parts of the wood and leaves notches, which gives the wood an amazingly authentic weathered look.

When it comes to newly manufactured wooden surfaces, a good preparation is important in every case. It is necessary to use medium fine sanding (final sanding with 120-150 grit), because the sandblasting process does not eliminate flaws! After polishing, veneered parts must have at least 0,6 mm veneer thickness. Furthermore, no guarantee can be given for irradiation.

Varnished parts are often coated with many different materials. In order to determine whether blasting is optimal and technically possible, a sample has to be made first. If it becomes apparent that blasting alone is too expensive, it is better to treat the coated products with a lye solution prior to the actual blasting process. Partner companies of 2M are happy to assist with this.